Comprehending the Significance of Welding Examination in Ensuring Structural Honesty and Security Across Various Industries

Welding evaluation is a crucial procedure that safeguards structural honesty and safety and security throughout varied markets. As we explore the details of welding examination, the inquiry develops: what are the most essential elements that contribute to reliable evaluation processes?

Duty of Welding Examination

While the stability of bonded frameworks is paramount to security and efficiency, the role of welding examination can not be overstated. Welding examination acts as an essential top quality control procedure that ensures the adherence to established standards and specs throughout the welding procedure. By systematically reviewing welds for issues, incongruities, and non-compliance, examiners play a crucial duty in securing the integrity of structures throughout various industries.

Welding examinations include a range of tasks, from pre-weld analyses to post-weld evaluations. These assessments not just determine potential issues prior to they intensify however additionally boost the general reliability and life expectancy of welded elements. Welding Inspection Milwaukee. Assessments help to verify the ability and expertises of welders, making certain that welding treatments are carried out properly and products are suitable

Additionally, a strenuous assessment method promotes conformity with regulatory needs and industry requirements, lessening the danger of tragic failings. By advertising a culture of safety and responsibility, welding assessment contributes significantly to both functional and economic effectiveness. Altogether, the role of welding examination is crucial, as it underpins the high quality, safety and security, and durability of welded frameworks important to contemporary framework and sector.

Kinds Of Welding Inspections

Recognizing the different kinds of welding evaluations is necessary for keeping the quality and safety of welded frameworks. Welding inspections can be classified right into several types, each offering a specific function in the analysis process.

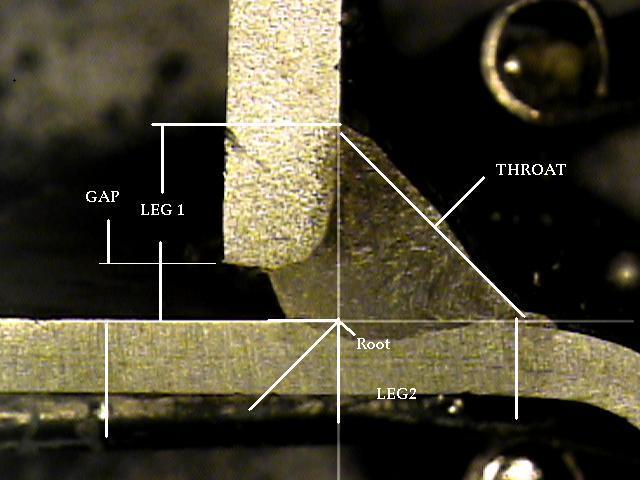

Visual examination is the most essential type, including a careful assessment of the welds with the naked eye or through zoom. This method aids recognize surface area defects such as cracks, incomplete fusion, or extreme spatter.

Following is non-destructive screening (NDT), that includes strategies such as ultrasonic testing, radiographic screening, and magnetic bit testing. These methods permit examiners to examine the integrity of welds without compromising the material's framework. Ultrasonic screening utilizes high-frequency acoustic waves to identify interior problems, while radiographic testing uses X-rays or gamma rays to imagine internal weld qualities. Magnetic bit testing, on the various other hand, works for spotting surface area and near-surface stoppages in ferromagnetic materials.

Destructive testing, though less usual, involves literally testing examples to comprehend the weld's mechanical properties. Each kind of evaluation contributes to an extensive analysis, making certain that welding satisfies industry criteria and safety requirements.

Industry Specifications and Rules

Establishing sector criteria and policies is critical for making certain the security and dependability of bonded structures. These standards work as standards for efficiency, top quality, and security, directing makers and inspectors in the execution of welding processes. Different companies, such as the American Welding Culture (AWS) and the International Company for Standardization (ISO), have created comprehensive requirements that determine treatments for welding practices, qualification of welders, and assessment techniques.

Conformity with these regulations not only boosts the high quality of welds however likewise minimizes threats linked with architectural failings. Details codes, such as the ASME Boiler and Pressure Vessel Code, overview needs for the building and construction of pressure vessels, guaranteeing they can withstand operational stress and anxieties. Additionally, national and local laws typically mandate adherence to these industry criteria, strengthening their relevance throughout industries like construction, aerospace, and automobile manufacturing.

Routine updates to these standards show advancements in technology and welding techniques, making sure that safety procedures stay appropriate. Hence, an extensive understanding and implementation of these requirements is important for welding professionals, cultivating a society of security and quality in welded frameworks.

Consequences of Poor Inspections

Insufficient evaluations can lead to serious repercussions in the welding sector, weakening the really guidelines and requirements created to ensure safety and security and architectural stability. The consequences my response of inadequate examinations can show up in different types, from immediate safety and security risks to lasting architectural failings.

Furthermore, inadequate examinations can stain a firm's reputation and outcome in lawful repercussions, consisting of penalties and lawsuits. Eventually, the implications of inadequate evaluations prolong beyond specific projects, influencing industry-wide criteria and public assumption, thus important link stressing the important requirement for extensive and efficient welding assessments.

Ideal Practices for Effective Examinations

Reliable welding inspections are paramount to making sure the honesty and safety and security of bonded structures. To attain optimum results, examiners have to abide by numerous ideal practices that improve the evaluation procedure.

Secondly, assessors need to possess the required credentials and accreditations appropriate to the welding procedures and products being checked out. Ongoing training and professional growth are crucial to remaining upgraded on market standards and technological innovations.

Furthermore, using suitable assessment tools and methods, such as aesthetic examinations, ultrasonic testing, and radiographic examinations, is essential for identifying defects that could jeopardize architectural stability.

Last but not least, extensive documents of the inspection procedure is vital. This includes recording findings, photos, and any kind of corrective actions taken. Accurate and clear coverage not just assists in responsibility however also aids in future inspections and upkeep. By implementing these best practices, organizations can dramatically boost the efficiency of their welding inspections and make certain risk-free, reliable procedures.

Conclusion

In final thought, welding examination is necessary for maintaining structural honesty and security throughout numerous industries. Focusing on reliable welding assessments is vital to make certain the security of workers, possessions, and total operational stability.

As we discover the details of welding examination, the inquiry develops: what are the most essential variables that contribute to efficient assessment processes?

Welding inspection serves as a critical high quality control procedure that makes certain the adherence web link to developed standards and requirements throughout the welding procedure. In amount, the function of welding inspection is important, as it underpins the top quality, security, and longevity of bonded structures important to modern-day framework and sector.

Numerous companies, such as the American Welding Society (AWS) and the International Organization for Standardization (ISO), have actually created thorough criteria that determine procedures for welding practices, qualification of welders, and inspection methods.

Ultimately, the ramifications of bad evaluations prolong beyond private jobs, impacting industry-wide standards and public assumption, hence stressing the critical requirement for effective and rigorous welding inspections.